The Centre of Excellence for Industrial Microwave Application Development was established in 2018 in collaboration with Industry Partner Enerzi Microwave Systems Pvt. Ltd. The primary objective of the center is to inculcate innovation and research culture in Ph.D. and Undergraduate students, enabling them to engage in cutting-edge, industry-oriented research and to excel as distinguished research professionals. The center houses state-of-the-art facilities in microwave heating technology and hybrid processing of engineering materials. To this end, it has persistently promoted collaborative projects in niche areas, pioneering high-quality research publications, intellectual property creation, and skill enhancement courses in Microwave and Allied Technologies.

MISSION

- To educate the students on Microwave systems and its components.

- To enable the students to learn about the phenomena of Microwave energy-material interactions and various applications of Microwave energy material processing.

- To expose the students to advanced research work, fostering the development of critical and creative thinking in their future endeavors.

- To familiarize students with Industry practices and challenges, enhancing their skills through this Industry-Academia collaboration

Dr. Vinayak R Malik

Associate Professor, Department of Mechanical Engineering,

KLS Gogte Institute of Technology, Belagavi

Email: vrm@git.edu

(Cell no. +91 9886406375)

Equipments | |

|---|---|

High-Temperature Microwave Sintering Furnace with Inert atmosphere provision (4.2KW) |  |

Lab Scale Microwave Sintering Furnace (0.8KW) |  |

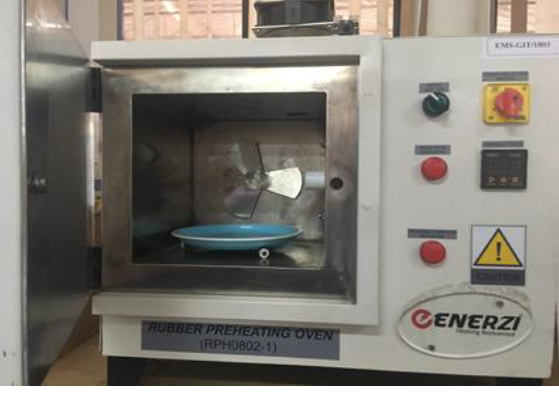

Rubber Preheating Microwave Oven |  |

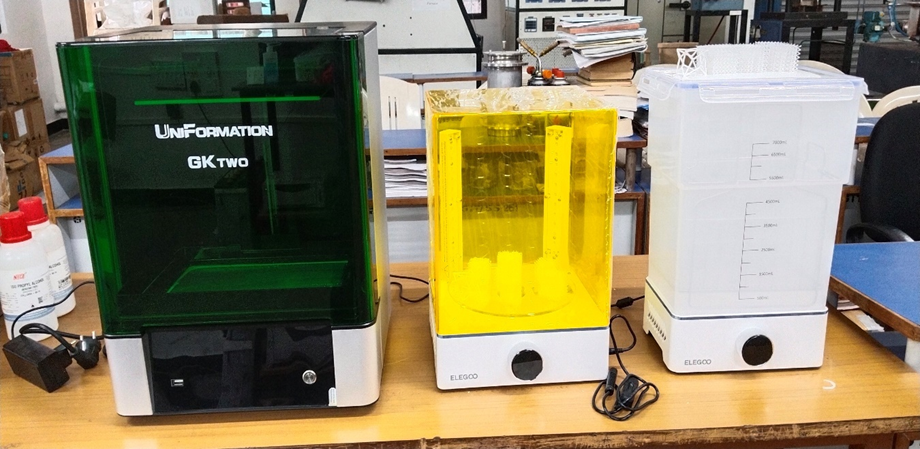

Uniformation GK2 LCD (m-SLA) Resin 3D Printer |  |

Horizontal Tensile Testing Machine (Tensometer-5KN) |  |

Hydraulic Press (25 Ton, Uniaxial) |  |

Spark EDM Machine |  |

Indigenously developed Bench top Dual Container Ball Mill |  |

Awards | |

|---|---|

Best project award at KSCST August 2022, 45th series for the project “Microwave Joining of 3D Printed Parts Applied to UAV wings” |  |

Third prize winner at IMTEX 2022 for the project “Non-Conventional Methods for Joining of 3D Printed Parts” held during June 2022 |  |

Second prize winner at IMTEX FORMING 2024 for “Development of Steel Foams Manufactured from Machining Waste for Automobile Crash Protection” in the field of metal forming |  |

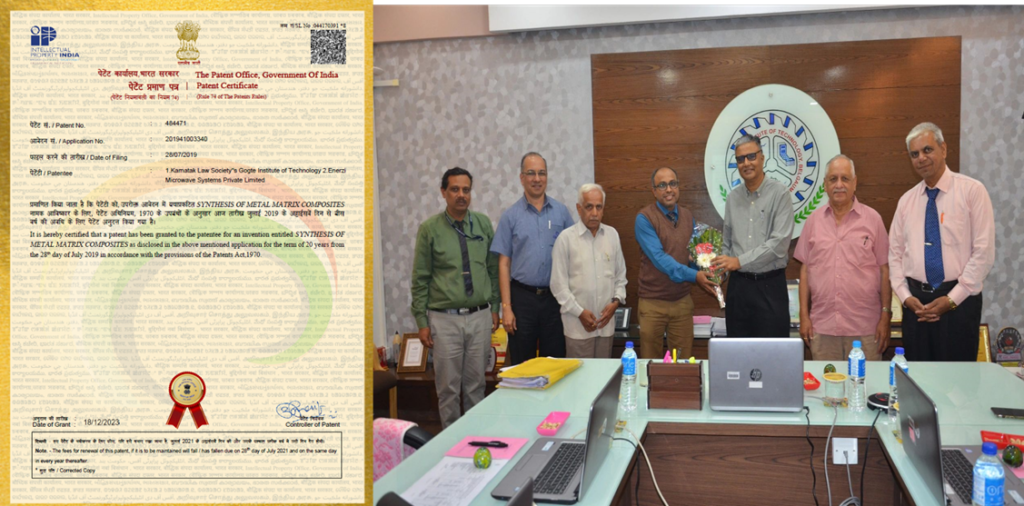

Grant of PATENT – A new Processing route was developed to manufacture tailored material for strategic applications jointly developed with the industry partner “Enerzi Microwave Systems Pvt Ltd |  |

- Padmakumar A. Bajakke, Vinayak R. Malik & Anand S. Deshpande; Particulate metal matrix composites and their fabrication via friction stir processing – a review; Materials and Manufacturing Processes; 2019, vol. 34, no. 8, pp. 833–881. DOI: https://doi.org/10.1080/10426914.2019.1605181

- Malik, V., & Kailas, S. V. (2018). Plasticine modeling of material mixing in friction stir welding. Journal of Materials Processing Technology, 258, 80-88. https://doi.org/10.1016/j.jmatprotec.2018.03.008

- Padmakumar A. Bajakke, Sudhakar C. Jambagi, Vinayak R. Malik & Anand S. Deshpande; Friction Stir Processing: An Emerging Surface Engineering Technique; In: Gupta K. (eds) Surface Engineering of Modern Materials, Engineering Materials, Springer Nature. DOI: https://doi.org/10.1007/978-3-030-43232-4_1

- Malik, V., Sanjeev, N. K., & Bajakke, P. (2020). Review on modelling of friction stir welding using finite element approach and significance of formulations in simulation. International Journal of Manufacturing Research, 15(2), 107-135. https://doi.org/10.1504/IJMR.2020.106851

- Bajakke, P. A., Jambagi, S. C., Malik, V. R., & Deshpande, A. S. (2020). Friction stir processing: an emerging surface engineering technique. Surface Engineering of Modern Materials, 1-31. 10.1007/978-3-030-43232-4

- Malik, V. R., Bajakke, P. A., Jambagi, S. C., Nagarjuna, C., & Deshpande, A. S. (2020). Investigating mechanical and corrosion behavior of plain and reinforced AA1050 sheets fabricated by friction stir processing. JOM, 72(10), 3582-3593. https://doi.org/10.1007/s11837-020-04323-0

- Tiwary, V. K., Ravi, N. J., Arunkumar, P., Shivakumar, S., Deshpande, A. S., & Malik, V. R. (2020). Investigations on friction stir joining of 3D printed parts to overcome bed size limitation and enhance joint quality for unmanned aircraft systems. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 234(24), 4857-4871. https://doi.org/10.1177/0954406220930049

- Bajakke, P. A., Malik, V. R., Jambagi, S. C., & Deshpande, A. S. (2020). Corrosion behavior of novel AA1050/ZnO surface composite: a potential material for ship hull. Materials Letters, 281, 128602. https://doi.org/10.1016/j.matlet.2020.128602

- Kumaraswamy, S., Malik, V., Devaraj, S., Jain, V. K., & Avinash, L. (2021). A study of shear friction factor in friction stir welding for developing a finite element model and its importance in the context of formation of defect free and defective weld. Materials Today: Proceedings, 45, 299-303. https://doi.org/10.1016/j.matpr.2020.10.651

- Bajakke, Padmakumar A., et al. “Microwave Processing of Engineering Materials.” Coatings. Springer, Cham, 2021. 31-55. https://doi.org/10.1007/978-3-030-62163-6_2

- Malik, Vinayak, and Satish V. Kailas. “Understanding the effect of tool geometrical aspects on intensity of mixing and void formation in friction stir process.” Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science4 (2021): 744-757. https://doi.org/10.1177/0954406220938410

- Tiwary, Vivek Kumar, P. Arunkumar, and Vinayak R. Malik. “An overview on joining/welding as post-processing technique to circumvent the build volume limitation of an FDM-3D printer.” Rapid Prototyping Journal(2021). https://doi.org/10.1108/RPJ-10-2020-0265

- Prabhu, Srinivas, Padmakumar Bajakke, and Vinayak Malik. “A review on in-situ aluminum metal matrix composites manufactured via friction stir processing: meeting on-ground industrial applications.” World Journal of Engineering (2021). https://doi.org/10.1108/WJE-01-2021-0001

- Naik HR, Manjunath, et al. “Effect of microstructure, mechanical and wear on Al-CNTs/graphene hybrid MMC’S.” Advances in Materials and Processing Technologies (2021): 1-14. https://doi.org/10.1080/2374068X.2021.1927646

- Bajakke, Padmakumar A., et al. “A novel ultrahigh conductive Al-Cu composite produced via microwave sintering and post-treated by friction stir process.” Advances in Materials and Processing Technologies (2021): 1-10. https://doi.org/10.1080/2374068X.2021.1945270

- Tiwary, V. K., Arunkumar, P., & Malik, V. R. (2023). Investigations on microwave-assisted welding of MEX additive manufactured parts to overcome the bed size limitation. Journal of Advanced Joining Processes, 7, 100141. https://doi.org/10.1016/j.jajp.2023.100141

- Malik, V. R., Bajakke, P. A., Jambagi, S. C., Bhajantri, V., & Deshpande, A. S. (2024). Comparative analysis of flipped and overlapped microwave sintered plus friction stir processed in-situ Al-Cu composites. Emergent Materials, 1-17. https://doi.org/10.1007/s42247-024-00781-3

- Bajakke, P. A., Malik, V. R., Jambagi, S. C., Bhajantri, V., & Deshpande, A. S. (2024). Unidirectional flipped multiple-pass friction stir process: an innovative step in the fabrication of in situ Al-Cu composites. The International Journal of Advanced Manufacturing Technology, 1-21. https://doi.org/10.1007/s00170-024-14248-6

- Kumar, M. Uday, et al. “Substantial enhancement of thermoelectric power factor of undoped CoSb3 skutterudites processed by microwave sintering.” Applied Physics A 130.9 (2024): 1-13. https://doi.org/10.1007/s00339-024-07812-0